Vapour blasting will rejuvenate and polish all your metal, plastic and rubber surfaces back to their original finish and in some cases better than original.

Vapour blasting is the only cost-effective way to achieve outstanding consistent results on all your parts. If you’re serious about your restoration projects like we are, you simply can’t overlook the benefits of vapour blasting.

We provide competitive rates, fast turnaround times and local or interstate delivery service. We are known for our specialist expertise and professionalism; we are your number one choice for motorcycle restoration

What is Vapour Blasting?

Vapour blasting is a process used to restore the surface of metals and composite materials. The process is well known for its appearance enhancing properties and it also increases the performance and durability of those components.

Our Results Gallery shows outstanding examples of the results of our vapour blasting services. The advantages of this process are:

Affordable and cost-effective

Gently and evenly cleans, de-scales and de-carbonizes irregular surfaces

Removes grime, oxidation and tarnishing without removing any of the underlying metal or substrate

Helps metal parts resist further staining and oxidation

Will not compromise any critical dimensions of machined surfaces, delicate parts and soft metals

Environmentally friendly - no toxic harmful chemicals are used

We use the latest 2020 state-of-the-art Vixen Treatment Systems equipment

How does the process work?

The basics of vapour blasting are water and media, mixed to create a slurry. This slurry is then applied under low pressure over the surface of a metal or composite material component.

This Ph neutral, stable cleaning action environment is extremely gentle. The media within the slurry peens and rolls over the surface of the component producing a very bright fresh and clean satin finish on metals and a rejuvenated finish on composite materials like rubber and plastics.

The key to vapour blasting is the flow of water-borne abrasives. The final finish is achieved due to the lubrication and flushing action of the water during the process, unlike dry blasting which etches away at the surface creating a profiled matt, dull finish. Dry blasting is better suited for preparing a component for paint or coating.

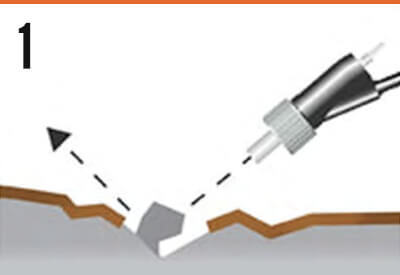

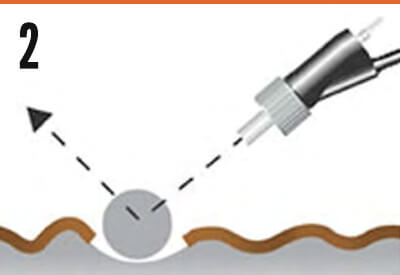

Dry grit & bead blasting processes

Dry grit and bead blasting processes are shown below in diagrams 1 and 2, which demonstrate the severe 90-degree ricochet that occurs when using these methods.

How Vapour Blasting works

Diagram 3 below shows how the vapour blasting method, also known as aqua blasting, works. The cushioning from the water, along with the altered angle for the media, produces a lapping effect that travels across the surface of the component being blasted.

A satin/polished finish is the result, desired and preferred by many industries.

We have streamlined our vapour blasting system and process to develop alternate sets of parameters that can be applied to achieve desired results across a whole range of substrates.

The manipulation of output air pressure, water volume and rate, along with media size and volume ratio, combined with the latest state-of-the-art equipment, provides high-end results unmatched by others.